13-June-2023

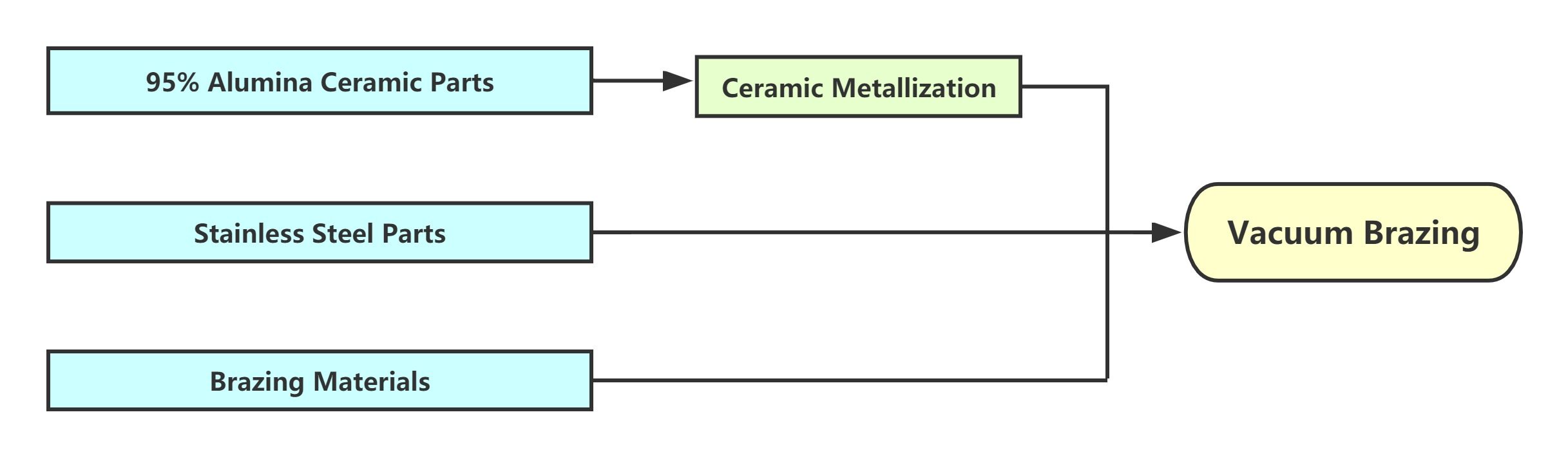

Take 95% alumina and 304 stainless steel as examples, the process of vacuum brazing is as follows.

1. 95% Alumina Ceramic Parts

95% alumina ceramic embryo suppression and high-temperature sintering according to the requirements of the design pattern. To ensure the size accuracy, the sintering ceramic parts are grinded.

2. Ceramic Metallization

First, ceramics should be selected and cleaned before metallization to meet the requirements of branch-free flying edges, no raised, no holes, smooth and clean ceramics. Second, the ceramic surface that needs to be metallic uses the wire printing with coated to print the molybdenum manganese paste. Third, the sintering and seepage of metallization are done under 1500°C. Then, Repeat the second coating of molybdenum and manganese paste, burning and seepage. Last, electroplated nickel metal film and sintered in hydrogen at 1200°C.

3. Stainless Steel Parts

The 304 stainless steel material is used to process stainless steel parts according to the design pattern. And then washed, nickel-plated, and hydrogen sintering at 1100 ° C.

4. Brazing Materials

Brazing means that the surface of the solid metal is infiltrated by some melting alloy. In this example, brazing materials are used for the ingredients and AG CU28NI1.5 materials. In order to further improve the infiltration performance, the metal surface and metal parts of the alumina ceramic parts use the surface nickel plating process.

5. Vacuum Brazing

According to the design requirements, the stainless steel parts, metallic ceramic parts, and brazing materials are fixed for assembly, and then put in a vacuum welding furnace to weld. Last, remove the welded parts for testing.