22-August-2023

Ceramic substrates are widely used in various fields such as power electronics, electronic packaging, hybrid microelectronics, and multi-chip modules due to their excellent thermal conductivity and air permeability. Among them, alumina ceramic is the most commonly used ceramic substrate material, and is favored for its good overall performance. The advantages of alumina ceramic substrates include excellent insulation properties, excellent high temperature resistance, high strength and hardness, excellent chemical stability and good processability. They effectively isolate circuits, withstand high temperatures, resist chemical corrosion, and meet complex processing and high-precision dimensional requirements. The main applications of alumina ceramic substrates are as follows:

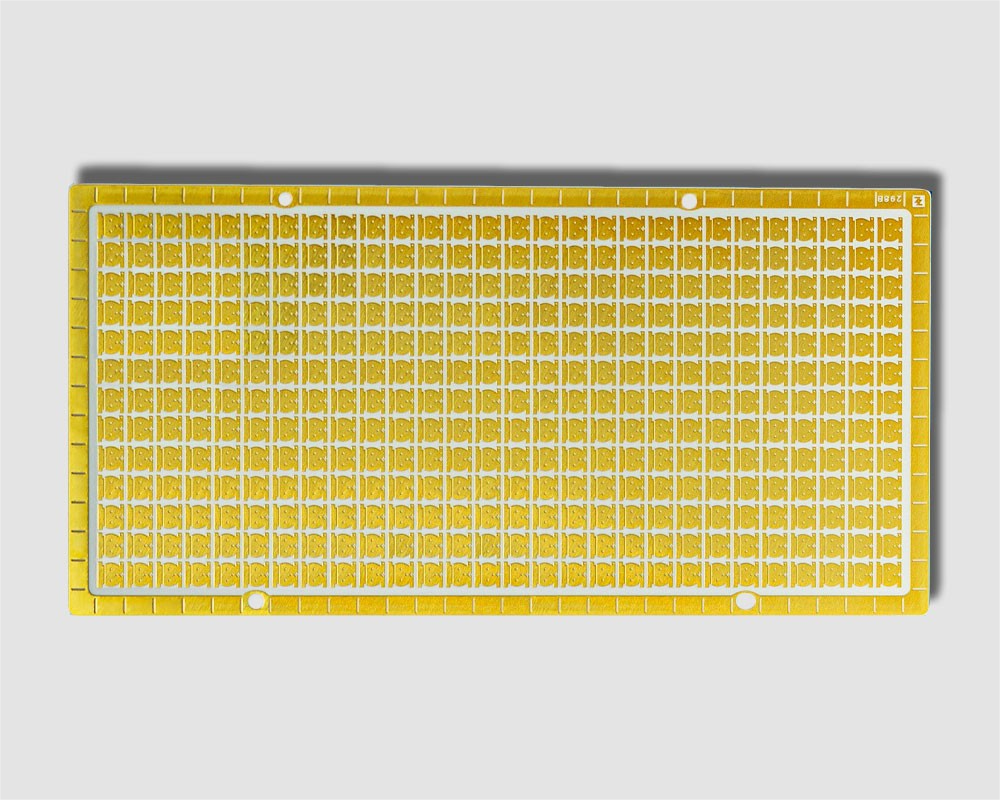

Ceramic Substrates for Chip Resistors

Alumina ceramic substrates for resistors have the advantages of small size, light weight, low thermal expansion coefficient, high reliability, high thermal conductivity, and high density. They greatly improve circuit reliability and wiring density, making them ideal carrier materials for chip resistor elements.

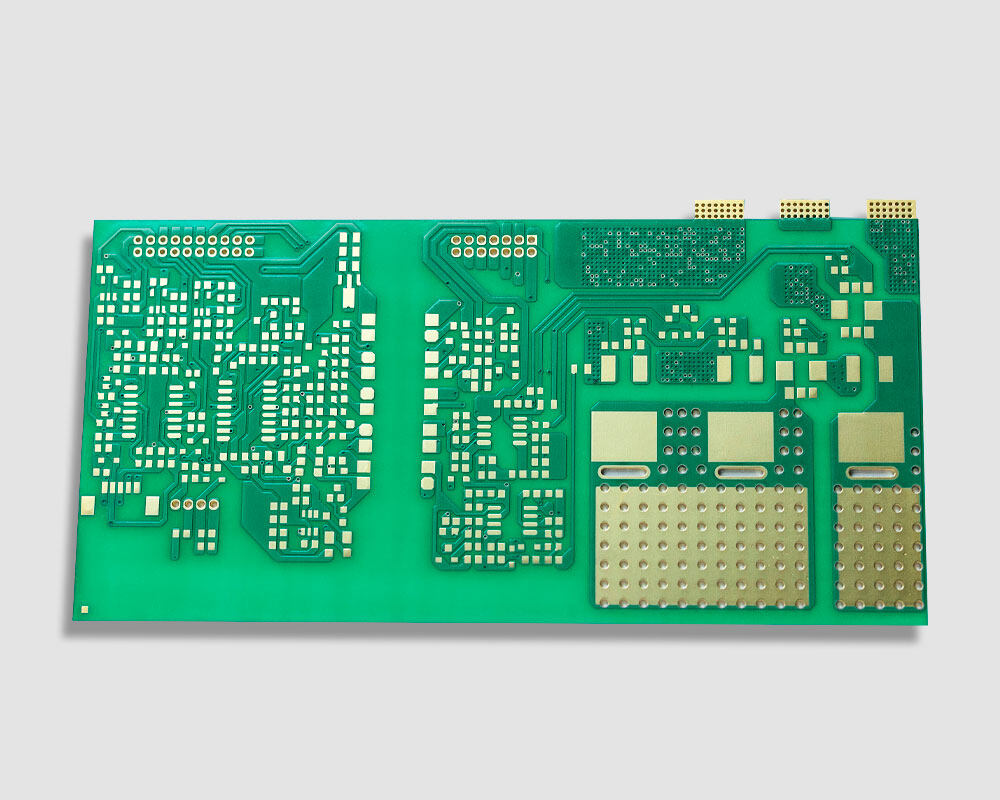

Ceramic Substrates for Hybrid Integrated Circuits

Hybrid integrated circuits involve packaging multiple components, at least one of which is active. These complex circuits are created by mounting components on metal-conductor-insulator boards produced by thick-film or thin-film processes. The substrate provides mechanical support for the circuit, serves as a deposition site for dielectric and resistive materials, and provides mechanical support for all passive and active chip components. Alumina, beryllium pillars, silicon dioxide, and aluminum nitride are common substrates for hybrid integrated circuits. However, smooth-surfaced alumina substrates are widely used in consideration of cost and performance. The quality and grade of alumina substrates vary depending on the alumina content. Common choices include 99.6% alumina for thin film circuits and 96% alumina for thick film circuits. Multilayer co-fired alumina ceramics are generally based on alumina green sheets with alumina content ranging from 90% to 95%.

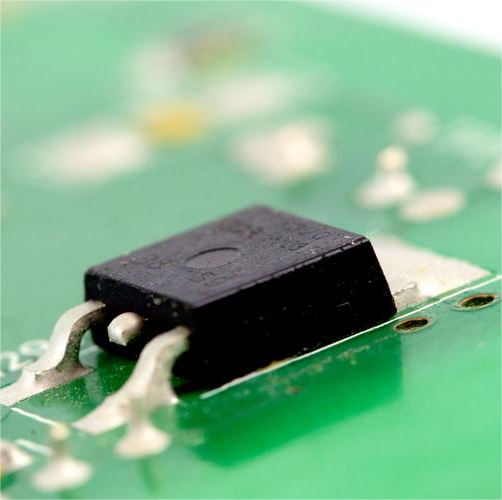

Power device substrates

For packaging power electronic devices, the substrate not only needs to provide basic wiring (interconnection) functions, but also needs to provide high thermal conductivity, insulation, heat resistance, voltage resistance and thermal matching capabilities. Cermet substrates such as DBC (Direct Bonded Copper) and DPC (Direct Plated Copper) have excellent properties in terms of thermal conductivity, insulation, voltage resistance, and heat resistance. They have become the material of choice for power device packaging and are gradually gaining market acceptance. The most common substrate material for device packaging is aluminum oxide (Al2O3), typically 96% aluminum oxide. The alumina substrate technology is mature and the cost is low.

Alumina Ceramic Substrates for LEDs

High-power LED heat dissipation substrates are mainly composed of ceramic substrates. The most commonly used high-power ceramic substrates on the market are LTCC (Low Temperature Co-Fired Ceramic) and DPC (Direct Copper Plating). Ceramic materials such as alumina and aluminum nitride are used. Alumina ceramic substrates for LEDs have high heat dissipation and air tightness, which improves the luminous efficiency and life of LEDs. Its excellent air tightness also has high weather resistance, allowing it to be used in various environments.