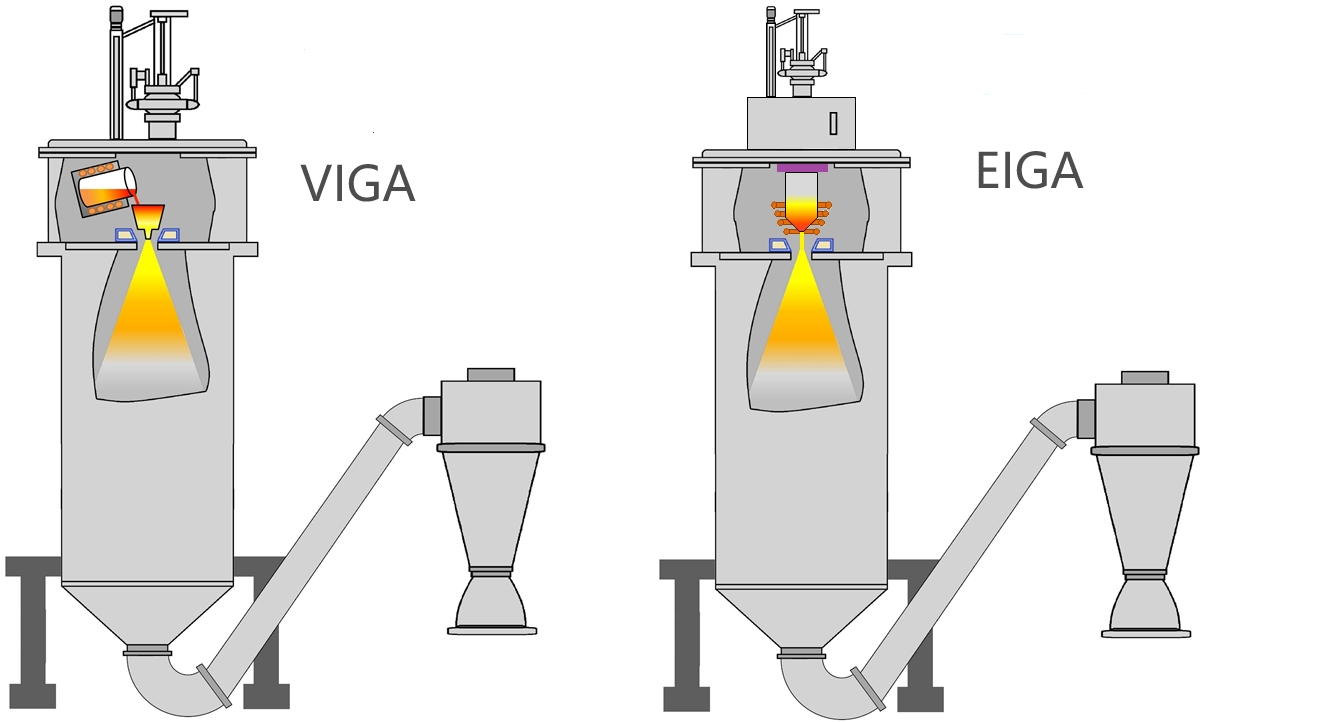

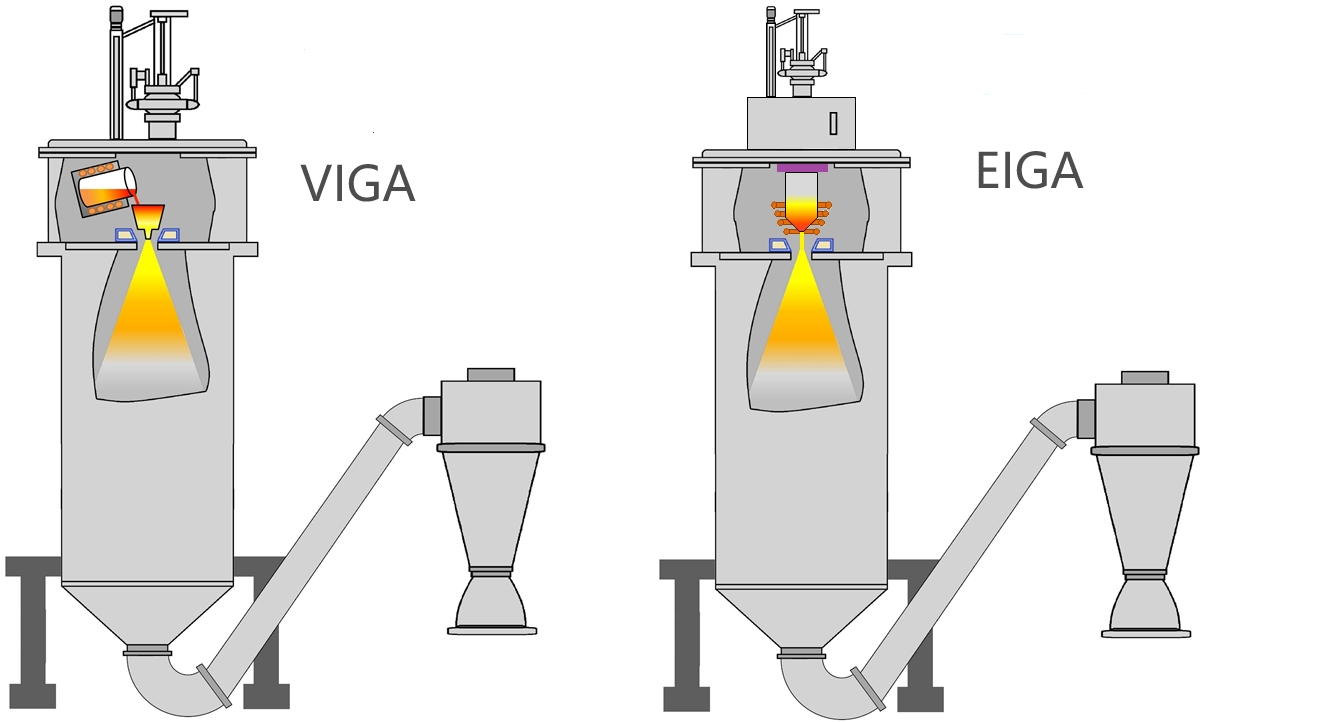

Gas atomization technology is an advanced method for preparing metal powders, which is mainly divided into two forms: vacuum induction melting atomization (VIGA) with crucible and electrode induction melting gas atomization (EIGA) without crucible. VIGA technology is suitable for the production of metal powders with a melting point below 1700 degrees Celsius, including alloy powders such as iron, nickel, cobalt, aluminum and copper. EIGA technology is suitable for metals with a melting point above 1700 degrees Celsius, such as titanium alloys, as well as active metals and their alloys.

(I) The operation process of vacuum induction melting atomization (VIGA) with crucible is as follows: First, the metal rod is placed in the crucible for melting. When the molten metal flows out, it is impacted by high-speed inert gas to form fine droplets. These droplets cool and solidify into spherical powders during flight. The advantages of VIGA are high fine powder yield and wide alloy applicability, but the disadvantage is that the use of ceramic crucibles may affect the purity of the powder, so subsequent purification treatment is required.

(II) The working principle of the crucible-free electrode induction melting gas atomization method (EIGA) is as follows: the metal rod is used as an electrode and melted in the induction coil. The molten metal flows out through the central hole of the atomizer and forms powder particles under the action of high-speed inert gas. EIGA technology has advantages in the preparation of active metals and high-melting-point metal powders. It is more cost-effective than the PREP method and does not use ceramic crucibles, which ensures the purity of the powder. However, the disadvantage of this technology is that the melting rate of the metal rod is difficult to control accurately. Improper operation may cause the rod to break or the liquid flow to be interrupted, which in turn leads to blockage of the guide tube.

These two gas atomization technologies have their own advantages and limitations. The selection of a suitable process depends on the characteristics and requirements of the metal powder to be prepared.

Product Page

Click here to contact us!