Product Parameters

| Index |

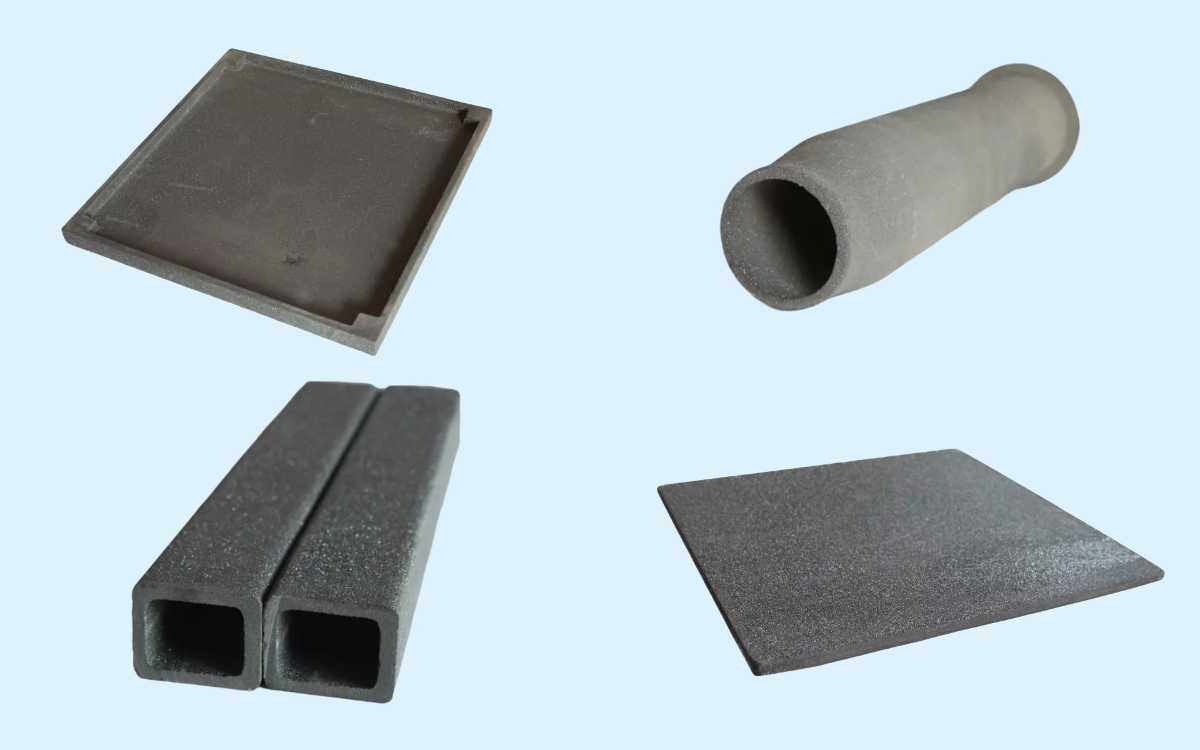

NSIC

(silicon nitride combined with silicon carbide)

|

SISIC

(reaction sintered silicon carbide)

|

RSIC

(recrystallized silicon carbide)

|

| Bulk density(g/cm³) | 2.75-2.82 | >3.02 | 2.60-2.74 |

| Porosity (%) | 10-12 | <0.10 | 15 |

| Compression strength(MPa) | 600-700 | / | ≥600 |

| Bending strength(MPa) | 250(20℃) | 250(20℃) | 90-100(20℃) |

| 160-180(1100℃) | 280(1200℃) | 100-120(1100℃) | |

| Young's modulus(GPa) | 220-260 | / | 280(20℃) |

| Thermal conductivity(W/MK) | 15(1200℃) | 45(1200C) | 26(1200℃) |

|

Thermal expansion(20-1000℃)

10-k¹

|

5.0 | 4.5 | 4.8 |

| Max.working temperature(℃) | 1500 | 1380 | 1650 |

| PH Resistanced | / | EXCELLENT | 1-14 |

| Moh's scale of thermal expansione | / | 13 | 0 |

| Si₃N:(%) | 20-40 | / | / |

| a-SIC(%) | 60-80 | / | 98.5 |

Tell us your needs, we have a Technical Consultant to provide you with Ceramic Solutions, click to consult!