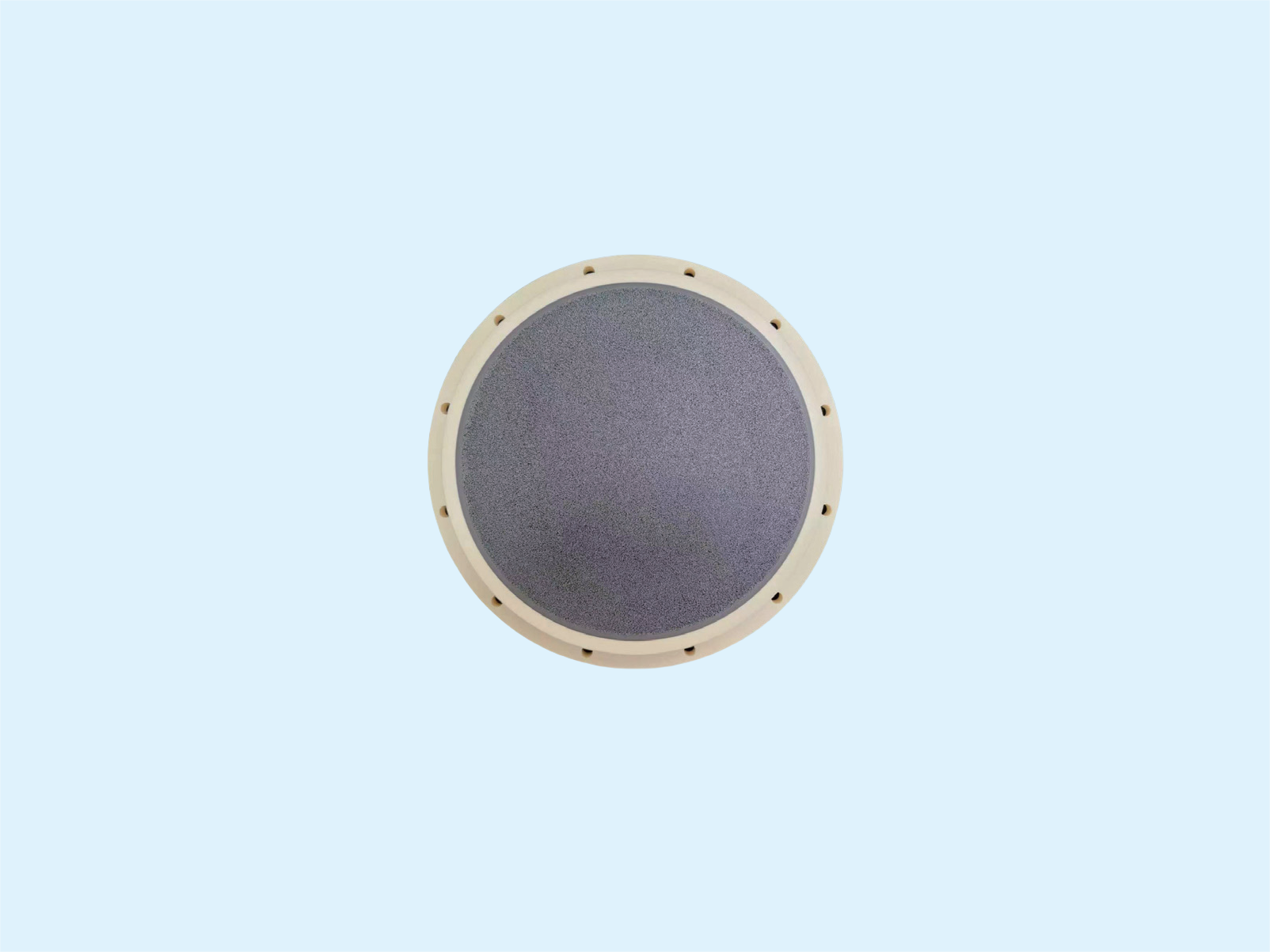

Cersol supplies Wafer Vacuum Chucks for dicing, grinding, cleaning and inspection of semiconductor wafers. Wafer Vacuum Chuck, also known as "Anychuck" or "Porous Chuck", this product is designed to provide secure, uniform vacuum holding of wafers. We offer multiple customization options to meet your unique production needs.

When working, the small holes on the porous ceramic are used to extract the air between the silicon wafer and the ceramic surface, so that the adsorbed object (usually a wafer) and the ceramic surface are at low pressure. The adsorbed object is adsorbed on the surface of the Wafer Vacuum Chuck due to the air pressure and is thus fixed.

Since the pores of porous ceramics are very fine, when the surface of the workpiece is attached to the vacuum suction cup, no adverse factors such as scratches or dents on the surface will be caused by negative pressure.

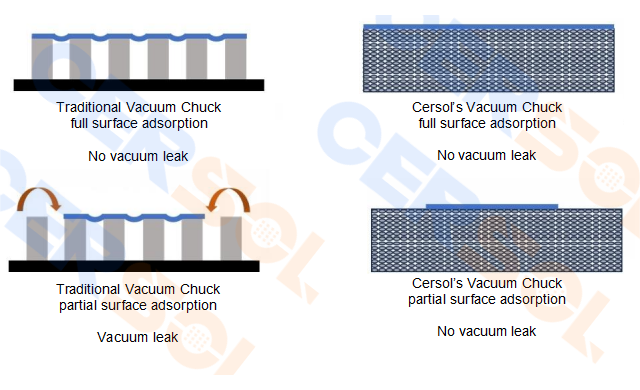

Vacuum chucks usually match the standard size of wafers, and different sizes of wafers correspond to corresponding sizes of chucks, which generally cannot be mixed. For example, a 150 mm (6 inch) chuck can hold a 150 mm wafer. If you want to be compatible with 4 inch wafers, you may need to replace the chuck or install a fixture.

As shown above, traditional vacuum chucks depend on full‑surface contact for airtight sealing. If the workpiece isn’t an exact match, air will seep through, and you’ll have to install a new chuck every time the part size changes.

Cersol's Wafer Vacuum Chucks, by contrast, uses partial‑suction zones to create localized vacuum pockets. It maintains a tight seal regardless of workpiece size, allowing a single chuck to handle multiple dimensions without air leaks.

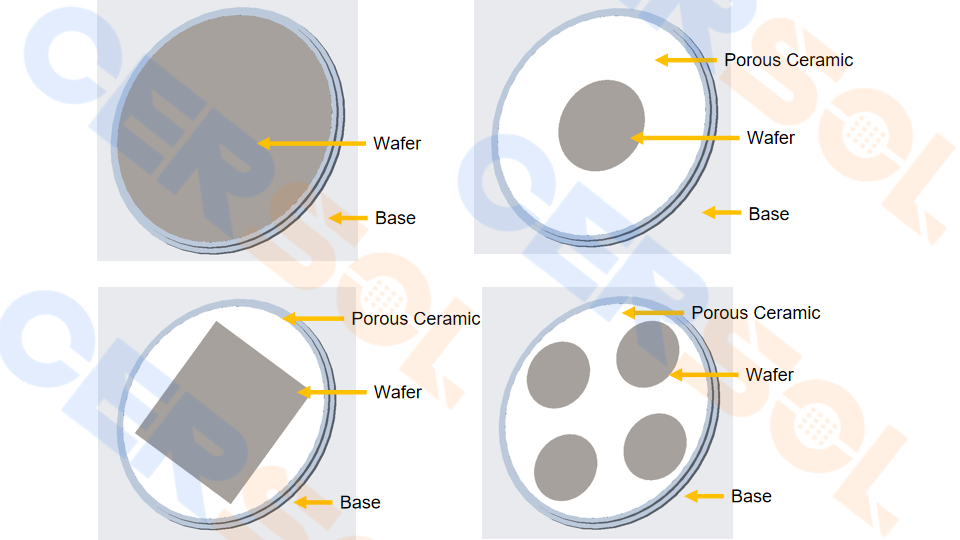

Cersol’s Vacuum Chuck provides a single, versatile solution for handling workpieces of varying dimensions and profiles. It can firmly secure thin parts—regardless of diameter or shape—for operations such as suction-based holding or precision polishing, eliminating the need to switch chucks when workpiece sizes change. In addition, it reliably adsorbs a broad spectrum of materials, including substrates, ceramics, wafers, and films.

Note: The choice of porous interface material should be matched to the specific workpiece composition. Our technical specialists are available to recommend the optimal porous medium for your application.

Cersol's Wafer Vacuum Chuck is suitable for a variety of sizes and shapes of adsorbents